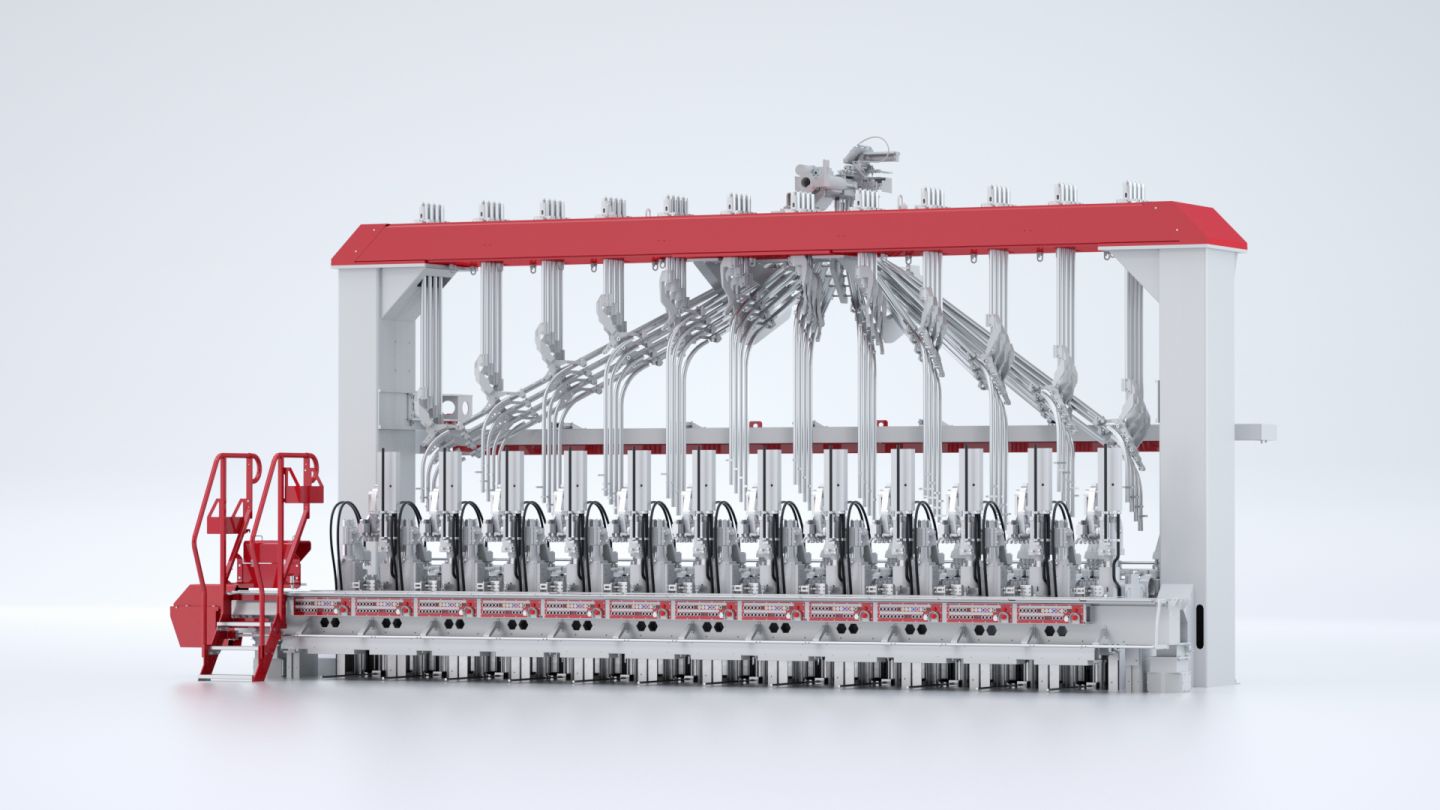

Ultimate servo electric forming solution

The servo electric driven NIS machine is the ultimate forming solution from Bucher Emhart Glass. The servo mechanism technology ensures that the NIS Machine outperforms traditional IS machines through better and precise motion control, perfect repeatability and faster and more precise setup time.

The use of servo electric motors reduces not only the noise level of the machine, but also significantly lowers the energy consumption.

The extended center distances of 5" TG and 95mm QG together with the conversion features DG<->TG<->QG make the NIS the most flexible high performance machine available today.

| NIS | 6 1/4" Double Gob | 5" Triple Gob | 95mm Quad Gob | ||||||

|---|---|---|---|---|---|---|---|---|---|

| B&B | P&B | NNPB | B&B | P&B | NNPB | B&B | P&B | NNPB | |

| Min. Height under Finish | 95mm | 75mm | 75mm | 95mm | 75mm | 75mm | 70mm | 70mm | 70mm |

| Max. Height under Finish | 365mm | 345mm | 345mm | 365mm | 345mm | 345mm | 250mm | 250mm | 250mm |

| Max. Body Diameter | 121mm | 121mm | 121mm | 90mm | 90mm | 90mm | 65mm | 65mm | 65mm |

| Max Finish Diameter | 48mm | 83mm | 50mm | 48mm | 70mm | 50mm | 35mm | 50mm | 38mm |

Standard Features

- FlexIS control system

- Servo Electric Gob Distributor

- Constant Cone suspended delivery system

- Parallel Blank and Blow Mold

- Quick Change Plunger mechanism

- Pneumatic Control Module (Blank and Blow Side)

- FPS valve technology for Plunger Up, Counter Blow and Final Blow

- VertiFlow blank mold cooling

- Neck Ring cooling

- VertiFlow blow mold cooling

- VertiFlow Assist

- High/Low deadplate cooling

- Automatic lubrication system with 4 zones

- Vacuum Assist Blow Side

Servo Electric Mechanisms

- Blank Mold Open and Close MOC (2 motors)

- Baffle Mechanism

- Invert Mechanism

- Blow Mold Open and Close MOC (2 motors)

- Blowhead

- Takeout Mechanism

- FlexPusher

Optional features

- Blankside InVertiFlow mold cooling

- FPS valve technology final blow

- Vacuum assist blank side

- Integrated dead plate guide air

- Plunger Process Control (PPC) -enabling closed loop control)

- Temperature Control System (TCS) or BlankRadar - enabling closed loop control

- Blankside lifting device

- Variable Center Distance tong head VCD TG, QG

- Blank side Barrier

Benefits

- Servo-electric mechanisms provide precise, repeatable motion

- Allows for 5" Triple Gob production run at the same speed as Double Gob

- Allows for 95mm Quad Gob production run at the same speed as Triple Gob

- Lower, more accessible section

- Reduced compressed air usage

- Substantial noise reduction for a quieter work environment

- Improved convertibility: 6 1/4 DG - 5" TG - 95mm QG

- Three fixed plunger position heights

Downloads

TNB289 - New Standard for all BEG Forming Machines

PDF | 19.10.2020

TNB256 - VertiFlow Assist for NIS machines

PDF | 20.10.2020

TNB235 - Constant Cone Delivery

PDF | 26.10.2020

TNB240RevB - Blank Side Panel 601-416-00

PDF | 28.10.2020

TNB292 - 4000 Series Plunger Mechanism

PDF | 11.11.2020

TNB311 - IS standardization.pdf

PDF | 20.04.2023

TNB318 VCD Tong Head.pdf

PDF | 11.01.2024

TNB319 - NIS Neck Ring Coooling Nozzle.pdf

PDF | 17.01.2024

TNB321 - V-Baffle.pdf

PDF | 17.06.2024

TNB322 - Blow Side Lifting Device_3.pdf

PDF | 17.06.2024